Click here for PDF Version for viewing or printing.

For additional technical help call our friendly staff at 800-959-6130

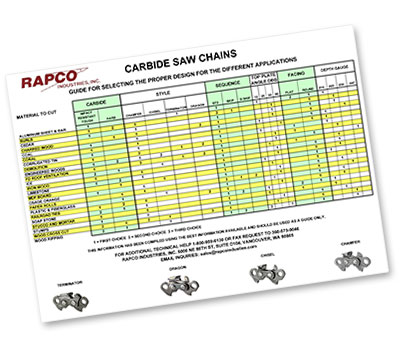

Selecting a Design: Choose the right chainsaw chain for your application! Our selection guide can answer many of your questions on selecting the right saw chain for:

Fire Department Roof Venting

Demolition

Iron Wood

Wood Crosscut & Ripping

Railroad Ties

Stumps

Burls

Charred Wood

Corrugated Tin

Aluminum Sheet & Bar

Paper Rolls

Plastic & Fiberglass

The Ultimate Guide to Choosing the Best Chainsaw Chain

For professionals in the forestry or paper industry, demolition experts, fire departments and anyone who has challenging cutting conditions, finding the best chain saw, or what some people call a blade, is crucial to getting the job done efficiently and safely. With so many options available in the market, making the right choice can be challenging. But don’t worry, we are here to help. Read on to learn everything you need to know to choose the best chainsaw chain.

Understanding Chainsaw Chains:

You’ll want to know the Pitch, Gauge, and number of Drive Links when you are ready to order or buy a chain.

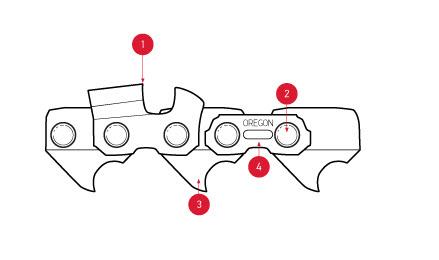

It’s important to first understand the various components of a chainsaw chain. Typically, a chainsaw chain is made up of four main parts – the cutter (1), preset (2), tie strap (2), and drive link (3). The cutter tooth has a cutting edge and a depth gauge (also called a raker). The depth gauge is responsible for controlling the depth of the cut each cutter makes. The drive link is used by the saw’s drive sprocket to engage and advance the chain around the bar. The presets and tie straps connect all the chain components together with the drive links and cutting teeth.

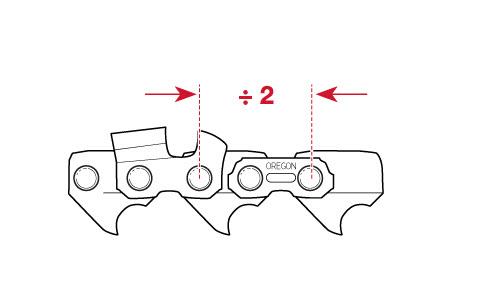

There are different sizes of chains available for chainsaws. These sizes are described as the chain pitch. The pitch of a chain is the distance between any three consecutive rivets divided by two. The standard modern-day pitches of chains are 1/4” (.250), .325”, 3/8” (.375), .404” and the larger 3/4” (.750”) for harvester saws.

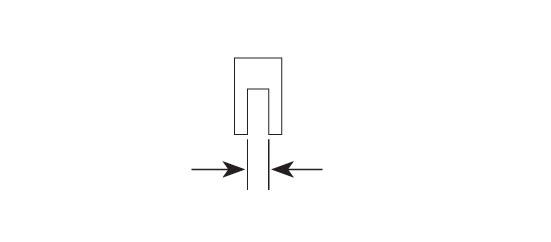

Besides the pitch there are also different gauges of chain. The gauge of a chain is the drive link’s thickness where it fits into the groove of the bar. The standard gauges today are .043”, .050”, .058”, and .063”. There are also larger gauges of .080” and .122” for wood processors and harvester saws.

Manufactures often stamp the drive links of their chains with one or two digits to designate the pitch and gauge of a chain. Sometimes it’s necessary to refer to the chain manufacturer’s website to decode their designations. It’s very important to match the number of drive links, pitch, and gauge of the chain that will fit your saw. If you don’t use the correct drive link count, pitch and gauge the chain will not fit correctly and can quickly damage your saw.

Types of Chainsaw Chain Cutters and Cutter Sequences:

Chainsaw chains primarily come in the form of two types of cutters, chisel and semi-chisel, with variations of each. Chisel cutters have a square-shaped cutting corner that is very sharp, making the chain cut faster and more aggressively, with the tradeoff of dulling more quickly and requiring more frequent sharpening. Semi-chisel cutters have a more rounded cutter edge providing a longer period between sharpening.

Chainsaw chains have left-hand and right-hand cutters that alternate with the sequence of the spacing between cutters. Chainsaw chains also have different cutter configurations or sequences: standard, semi-skip and skip sequence. A standard sequence chain has a cutter every two drive links, with a single tie-strap between cutters. A semi-skip chain alternates between two standard sequence cutters and then three drive links with a cutter throughout the length of a chain. There is also a skip or full skip chain that has a cutter every three drive links. Generally, most chainsaw chains have a standard sequence and skip chains are generally used on saws with lower-power motors or longer bars.

Bar or Chain Length:

Although it’s possible to get different length bars for a saw, it’s safest to use a bar length matched to the size of the material that is going to be cut. The best length of bar for a saw is generally going to be at least 2 inches longer than the material you’re cutting. The length of a bar is measured when mounted on a saw as the exposed distance between where it comes out of the saw power head to the tip of the bar, not the whole length of the unmounted bar. Longer bars require more power to drive a chain with enough speed to cut material efficiently. Longer bars are also more prone to hazardous kickback.

Brand Reputation:

When it comes to chainsaw chains, the brand reputation is important. You want to choose a trusted brand that has a proven track record of making high-quality chains. This ensures that the chain will perform well, last a long time, and meet all your cutting needs. One brand that may not be well-known to the general public but which is highly regarded by professionals for over 40 years in the industry for its durability and cutting performance is Rapco Industries. To learn more please visit their website at: https://rapcoindustries.com/

Price:

While it’s important to choose a high-quality chainsaw chain to get the job done effectively, it doesn’t mean you have to break the bank. Look for a chain that offers a great balance between durability, performance, and price. Don’t just fall for cheaper options, as they may compromise the chain’s quality and durability.

Conclusion:

In conclusion, choosing the best chainsaw chain for your project requires careful consideration of multiple factors such as the type of cutter, chain length, brand, and price. By understanding different chain components, types, and their unique features, you can make an informed decision that meets your