Everything You Should Know About the Types of Saw Chains Before You Buy

Even if you’re a seasoned professional cutting through dense hardwood or a homeowner trimming firewood, the chain you select directly impacts your results. With a wide range of cutter styles, chain sequences, and materials available, understanding the distinctions between saw chain types is essential before making a purchase.

This comprehensive guide covers every critical factor, from cutter design to wood type compatibility, and helps you determine when it’s time to upgrade to a high-performance carbide-tipped chain.

Understanding Saw Chain Anatomy and Performance

Every chainsaw chain, regardless of pitch or brand, is made up of three primary elements:

- Cutters: Teeth that perform the cutting, are shaped, and are sharpened for specific applications

- Drive Links: Fitted into the bar’s groove to drive the chain forward

- Tie Straps and Presets: Connect links and hold the structure together

The cutter type, cutter sequence, and grind profile largely dictate the performance of a saw chain. These elements determine how fast a chain cuts, how often it must be sharpened, and how well it handles dirty, frozen, or hardwood materials.

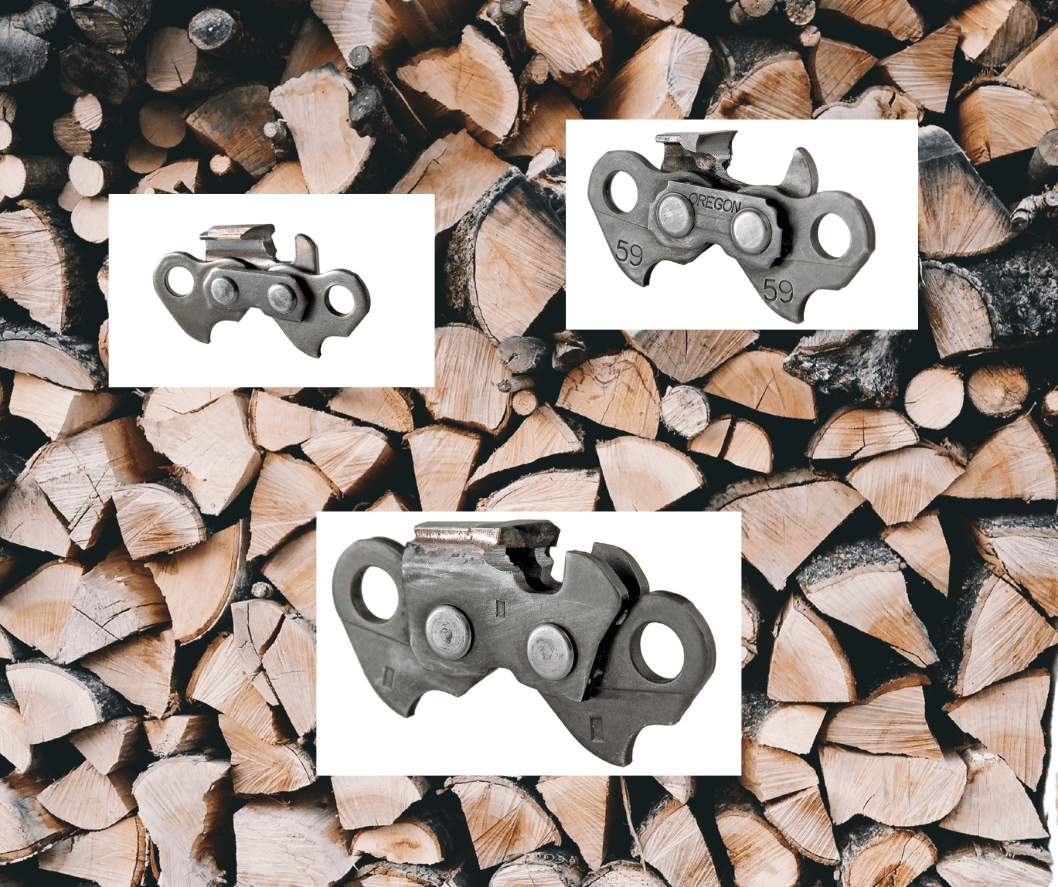

Types of Saw Chain Cutters Explained

Saw chain cutters are engineered for different tasks. Understanding the four primary cutter styles allows you to select the correct chain based on your cutting environment, wood type, and frequency of use.

Full Chisel Cutter

- Shape: Sharp 90-degree square-cornered tooth

- Best For: Fast, aggressive cutting through clean hardwood

- Downside: Dulls quickly in dirty or abrasive conditions

- Application: Forestry, hardwood felling, production environments

Semi-Chisel Cutter

- Shape: Rounded corners with more surface area

- Best For: General-purpose cutting in softwood, dirty or frozen wood

- Downside: Slower cutting speed than full chisel

- Application: Firewood, residential cutting, storm cleanup

Square Ground Cutter

- Shape: Similar to full chisel but sharpened with a square file for superior sharpness

- Best For: High-speed hardwood cutting

- Downside: Difficult to sharpen; requires specialized equipment

- Application: Professional logging and competition cutting

Specialty Cutters (Carbide-Tipped, Chamfer, Dragon, Terminator)

- Shape: Varies; usually includes impact-resistant carbide tips

- Best For: Dirty, frozen, nail-embedded wood, demolition, rescue applications

- Downside: Higher upfront cost; must use diamond tools for sharpening

- Application: Industrial, demolition, fire departments, high-abrasion environments

For chain style breakdown and selection tips, visit Carbide Chainsaw Chains Home

Matching Saw Chain Types to Cutting Needs

Choosing the best saw chain depends heavily on the wood type and the conditions you expect to cut in. No single chain style is ideal for every situation. Below is a decision matrix aligning cutter types to specific environments:

| Wood Type / Condition | Recommended Cutter Type | Suggested Upgrade |

| Clean hardwood (oak, maple) | Full chisel or square ground | Carbide chisel |

| Softwood (pine, fir) | Semi-chisel | Chamfer carbide |

| Frozen or wet wood | Semi-chisel or carbide flat | Flat-ground carbide |

| Dirty wood (mud, sand) | Chamfer or Terminator | Dragon or custom grind |

| Nail-embedded wood | Chamfer carbide | Terminator or Dragon |

| High-volume cutting | Square ground or carbide | Carbide chisel |

See our full breakdown on chain selection: How to Pick the Best Chainsaw Chain for Hardwood

How Cutter Sequences Affect Performance

In addition to cutter shape, the sequence of cutters (spacing between teeth) impacts how well the chain performs. There are three primary configurations:

Standard Sequence

- Cutter every two drive links

- Balanced chip removal and smooth operation

- Best for all-purpose and smaller bar lengths

Skip Sequence

- Cutter every three drive links

- Faster cutting on longer bars; better chip clearance

- Ideal for larger saws or dirty/frozen wood

Double Skip Sequence

- Cutter every four drive links

- Lowest resistance; designed for long bars and low-RPM saws

- Used in very specific industrial applications

Chain sequence should match saw power, bar length, and the wood density being cut. A mismatch may cause bogging, excessive vibration, or overheating.

When to Upgrade to Carbide-Tipped Saw Chains

Carbide-tipped chains are built for professionals who cut in abrasive, unpredictable, or extreme conditions. They feature tungsten carbide inserts that stay sharper up to 25 times longer than standard steel.

Upgrade to Carbide When:

- You frequently cut dirty, sandy, or frozen wood

- You encounter metal, nails, or composite materials

- You require extended cutting without downtime

- You are cutting dense hardwoods repeatedly

- You want to reduce chain replacement frequency

Carbide chains come in different designs: chisel for speed, chamfer for resistance, Terminator for impact, and Dragon for demolition.

Browse models and ordering details: Carbide Tipped Saw Chain Ordering

What Makes a Chain “The Best”?

The best saw chain is the one that balances speed, durability, and safety for your application. Key performance metrics include:

| Metric | Description |

| Edge Retention | Time between sharpenings |

| Impact Resistance | Withstands nails, dirt, and hard objects |

| Cutting Speed | Volume of material removed over time |

| Chain Stretch | How quickly a chain elongates with use |

| Vibration Reduction | Affects operator fatigue and control |

While budget chains may offer short-term savings, they degrade quickly under real-world use. Premium chains like Rapco’s carbide-tipped line are manufactured with:

- Silver-soldered carbide tips

- Dual carbide grades (impact and endurance)

- Custom lengths and grind profiles

- Precision link configurations for every saw model

See why professionals choose Rapco: Carbide Chainsaw Chains Home

Sharpening Tools and Maintenance Considerations

Sharpening requirements vary drastically by chain type:

- Standard steel chains use round files or bench grinders

- Square ground chains need square files and guides

- Carbide-tipped chains require diamond grinding tools

Rapco offers:

- Diamond bench wheels

- Handheld rotary burrs

- Chain re-sharpening services using original manufacturing equipment

Proper sharpening extends chain life, maintains speed, and prevents dangerous kickback. Chains that are improperly sharpened or mismatched to their application can cause engine strain and reduced productivity.

Final Considerations Before Purchase

Before buying any saw chain, collect the following information:

- Pitch (e.g., .325″, 3/8″, .404″)

- Gauge (.043″, .050″, .063″, etc.)

- Drive link count (to fit bar length)

- Bar compatibility (check manufacturer specs)

- Power output of your saw (for appropriate sequence and cutter type)

- Primary cutting environment (clean vs dirty, hardwood vs softwood)

Most importantly, consider long-term use. Chains that cost more up front but last significantly longer can reduce total operating cost over time.

Conclusion: Choose the Right Chain, Not Just the Right Fit

There’s no one-size-fits-all in chainsaw chains. Understanding cutter styles, grind profiles, material durability, and sequence types allows you to make a well-informed decision.

Whether you’re felling timber or maintaining your backyard, the right chain will enhance efficiency, improve safety, and protect your equipment investment.